Welcome to the world of tube forging.

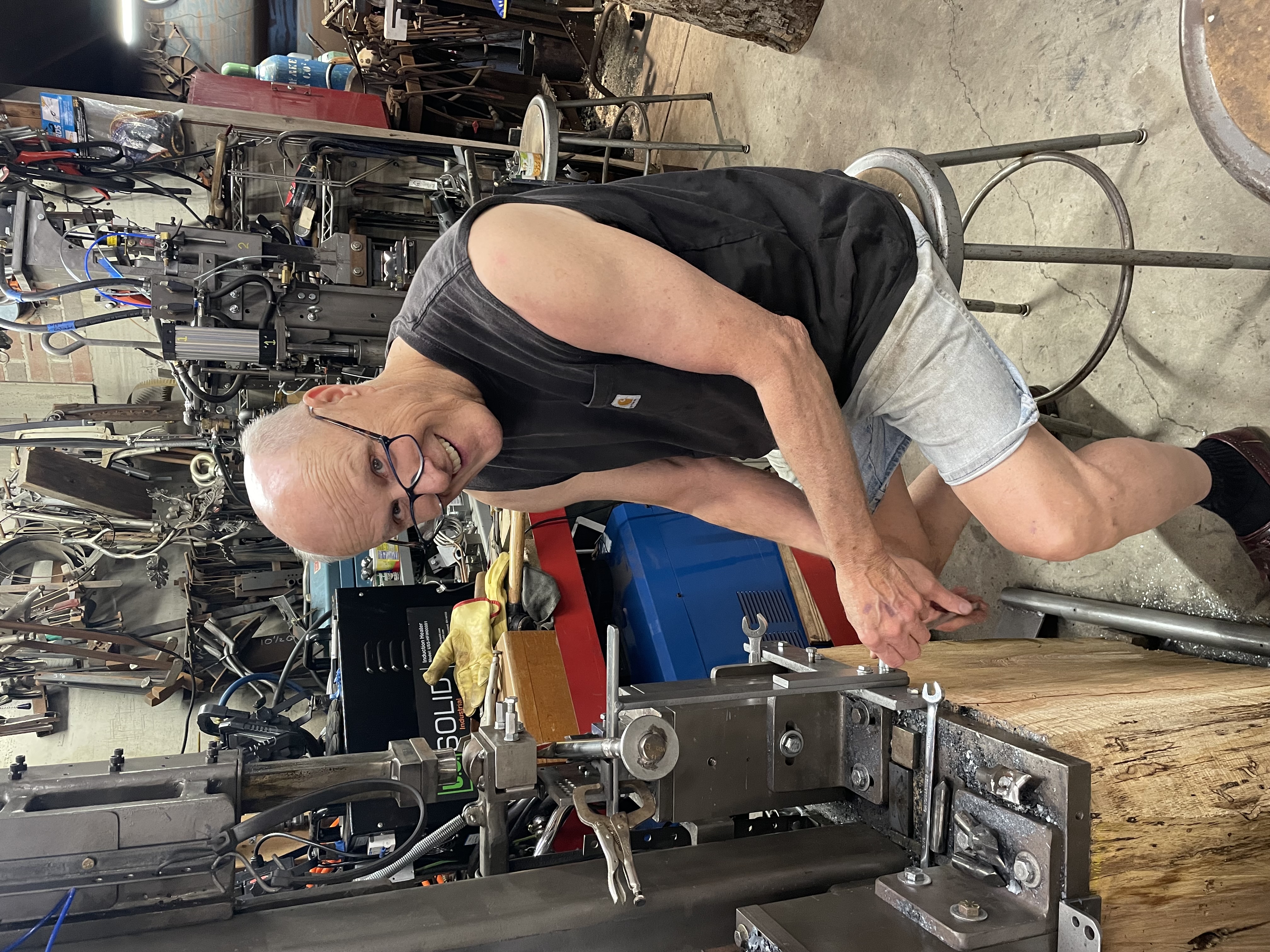

Let me introduce you to Dr. Bruce Jarrell. He has been a hobby blacksmith for over 30 years. For the past 10 years, Bruce has been concentrating on forging art with botanical themes. His goal has been to replicate natural elements such as flowers and leaves as delicate as they exist in nature. His early efforts involved forging schedule 40 pipe, using specialty dies he created himself, on his 155# ram Big Blu power hammers. His results were very good, but he wanted to do better. His efforts were restrained by his power hammers. They did not have sufficient control for him to be able to forge thin tubing, which he considered the gold standard for achieving his goals.

During the fall of 2018, Bruce saw one of my early power hammer designs. It was a Cricket I took to MASA's fall blacksmith conference at Tuckahoe, MD. It had a 15# ram and the control he was looking for. Bruce enthusiastically asked if I would build him one. I responded with "Sorry, I don't build to sell". My only goal (with regards to hammers) in those days was to design a power hammer that anyone who could weld and had basic metalworking tools could build. I had produced a dozen very detailed YouTube videos showing how to build them.

Bruce had been an acquaintance of mine for several years before that fall. He always brought examples of his work to conferences. Not just botanical themes, but also an range of eclectic forgings from plates to miniatures of early American furniture. I had a great respect for his skill in many ways. I saw him again at MASA's Gichner's Memorial Conference the following January. He was still excited about the Cricket and told me more about desire to have one made for him. He invited me to visit his shop to see how he forged with his current equipment.... It was late spring before I made it to his shop. He showed me more of his work and demonstrated some of the processes he used to produce it.

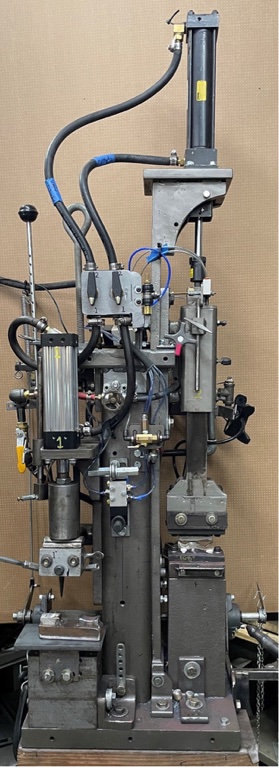

I was impressed and agreed he could benefit from one of my hammers. I still was of a mindset that I didn't build to sell though. I likely saw him at more conferences that year (2019), including again at the MASA fall conference in the fall. I started liking the thought that I could help him advance his capability to meet his forging goals. I didn't tell him, but made plans to build him a specialty hammer to help him do some of the work he couldn't do with his Big Blu hammers. At the next Gichner's Memorial conference in January of 2020, I brought him a specialty hammer with an unguided ram that struck tooling that was held in a stationary arm. The cylinder bracket and arm could be repositioned vertically to accomodate different tooling and forged objects. The anvil could also be moved forward and back to allow positioning of various lower dies.

I knew this would not be the final configuration of this hammer, but it was a start to be able to move work to a power hammer he could not do with his larger hammers. I merely replaced a tool I saw him using in his shop (on an anvil) when he was working on leaves and fullering other objects.

Bruce took the hammer home with a huge smile on his face. Over the next few months (yes, during the early days of covid), we modified the original configuration (changed the stationary arm into a swinging arm) and added a second forging station on the right side. Bruce would advise me what he would like to do with the hammer.... and we would make a plan. We spent many Sundays working in my shop, planning and upgrading to add capabilities.

This is what that first hammer became... A dual-station hammer with a shared air circuit.

This is what that first hammer became... A dual-station hammer with a shared air circuit.

Over the next three years, I built two more dual-station hammers for him, adding features to support his wish lists (we collaborated on function). The second hammer is more powerful than the first. The third hammer is slightly smaller (easier to move) and was built to be the hammer that would be used for demonstrations.

Bruce re-positioned controls (moved valves) so he could more easily do operational procedures while he was sitting. He set up foot pedals (rather than using treadles) because they are more friendly while sitting on a stool while forging.

There are videos on this page with Bruce extolling the benefits of all three (Left Panel).

All in all, it has been a collaborative experience to bring these hammers to their current configurations and capabilities.... one that I am happy to have had the partner I did.

I am blessed and thankful to be able to call Bruce Jarrell my friend.